I am leaving Saturday morning to take our son back to college. I wish I could have made the trip to California for CHA but I am trying to be patient and wait for all of the new product information to start appearing on message boards and blogs. I think there are a lot of great new things in store for us.

Today's post is a little different. I use the Design Studio software virtually every day and I have become very familiar with the "things that don't work the way you expect them to" and the "ways to get around the problem." Lately, there have been a lot of people asking questions about how to do some of the slightly trickier things.

I made a file for a wagon wheel (actually a wheel for a pram) for a reader. I realized from a few other emails that even though I have done a video about "welding in a frame" and the need to "burp" the design, some people have trouble watching videos due to internet connection problems or they prefer something that can be printed out and referred to in hard copy. With that in mind, I did a "words and pictures" explanation of all the steps it took to make the wheel.

Start with a silhouetted circle. The George cartridge has many silhouetted shapes and I like it because the line is thinner than some of the others. In this case, the request was for a 2 1/2 inch wheel so I set the slider bar at 2 1/2. It is important to determine the finished size needed because you won't be able to "group" the components by keeping them in the same selection box since some of the pieces need to be resized and rotated.

Use the handle on the center right to narrow the rectangle to the same width as the line of the silhouetted circle. You could make it even thinner if that is the look you want - I thought it looked best when the lines were even.

To be sure that the rectangle will stay within the outer edge of the circle, change the height to 2.3 inches in the Shape Properties box. Click on the mat or press enter to make the change effective.

Next, move the rectangle to the center of the circle. You can use the pale gray plus signs in the middle of the shapes as a guide to be sure that the circle and rectangle are perfectly centered. If you have trouble seeing the plus signs, try using the 200 view.

Add a new page to the file and then click the preview eyeball. By previewing on a "clean page" you can see clearly the dark lines where the finished design will cut.

Here is the preview with the thin rectangle and the circle - the weld works perfectly. Now you need to add the other spokes of the wheel.

Select the rectangle and click copy and then paste.

Whenever you copy and past, the pasted image is placed in the exact position of the original image. You can tell that there are two images by the slightly darker line.

While the pasted rectangle is still active (with the handles showing), click the 90 degree box in the Shape Properties box - this will quickly rotate the item selected exactly 90 degrees and is a very handy shortcut.

Click paste again to add another rectangle and then type 45 in the rotate box in the Shape Properties box. This box allows you to set precise values for the rotation.

Finally, click paste one last time and then enter "-45" in the rotate box - this will turn the rectangle 45 degrees in the opposite direction so you will have the full wheel.

When you click preview and check the weld, you will discover that there is a problem - but there is an easy way to fix this.

The problem is created by the order in which the items were added to the design. The program seems to read the shapes in the order they were added to the mat. If you have only two items (a closed frame shape and one item inside) there is no problem with the weld. When you add a third item inside the frame you need to work from the inside out to be sure that the welds will work properly. It is generally easier to put your outer item on the mat to work with it and be sure that things line up properly. Then you can do the simple "burping" fix to make the welds read correctly.

Select the outer circle and click copy, then delete and then paste. The pasted object goes back to the mat in exactly the same position but it now has been added to the design after all of the other items. Think of it as letting out the air that was trapped within the design.

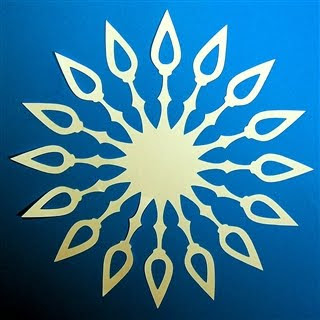

Now your preview will look like this and you can cut your wheel.

Here is the final cut. These are fairly quick to make, so if you need a set you can just create them over and over until you have enough. It will be a great day for Design Studio users when the program is updated and allows you to "group" a set of shapes that contain individual shapes that have been rotated or otherwise changed. This would allow you to then copy and paste the entire group as a unit!

I hope this was helpful to the new Design Studio users - for those of you who have already learned how to do this, maybe it was a good review. If you are a person who actually prefers videos here is a LINK to the post with the "welding in a frame" video. The example is different but the same principle applies to any items place inside a closed, outlined shape.

I'll be driving most of the day tomorrow so I won't be able to check comments or messages until late in the day. If you have any questions, please leave a comment or email me and I will reply as soon as I can.